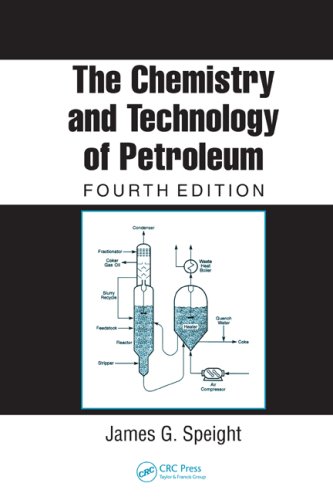

James G. Speight9780849390678, 0849390672

Like its bestselling predecessors, this volume traces the science of petroleum from its subterranean formation to the physicochemical properties and the production of numerous products and petrochemical intermediates. Presenting nearly 50 percent new material, this edition emphasizes novel refining approaches that optimize efficiency and throughput. It includes new chapters on heavy oil and tar sand bitumen recovery, deasphalting and dewaxing processes, and environmental aspects of refining, including refinery wastes, regulations, and analysis. The text also features revised and expanded coverage of instability and incompatibility, refinery distillation, thermal cracking, hydrotreating and desulfurization, hydrocracking, and hydrogen production.

A unique, well-documented, and forward-thinking work, this book continues to present the most complete coverage of petroleum science, technology, and refining available. The Chemistry and Technology of Petroleum, Fourth Edition provides an ideal platform for scientists, engineers, and other professionals to achieve cleaner and more efficient petroleum processing methods.

Table of contents :

9067_fm.pdf……Page 1

The Chemistry and Technology of Petroleum……Page 9

Preface to the Fourth Edition……Page 11

Preface to the First Edition……Page 13

Author……Page 15

Table of Contents……Page 17

Part I: History, Occurence, and Recovery……Page 35

Table of Contents……Page 0

1.1 Historical Perspectives……Page 37

1.2 Modern Perspectives……Page 44

1.3 Definitions and Terminology……Page 46

1.4.1 Petroleum……Page 48

1.4.3 Bitumen……Page 50

1.4.4 Wax……Page 51

1.4.6 Asphaltoid……Page 52

1.4.8 Kerogen……Page 53

1.4.9 Natural Gas……Page 54

1.5.3 Asphalt……Page 56

1.5.4 Tar and Pitch……Page 57

1.6.1 Asphaltenes, Carbenes, and Carboids……Page 58

1.6.2 Resins and Oils……Page 59

1.7 Oil Prices……Page 60

1.7.2 Oil Price History……Page 61

References……Page 62

2.1 Introduction……Page 65

2.2.1 Classification as a Hydrocarbon Resource……Page 67

2.2.2 Classification by Chemical Composition……Page 68

2.2.3 Correlation Index……Page 70

2.2.4 Density……Page 71

2.2.6 Viscosity……Page 72

2.2.8 Viscosity-Gravity Constant……Page 73

2.2.10 Recovery Method……Page 74

2.3 Miscellaneous Systems……Page 75

2.4.1 Identification and Quantification……Page 77

2.4.2 Future……Page 78

References……Page 79

3.1 Introduction……Page 81

3.2.1 Abiogenic Origin……Page 82

3.2.2 Biogenic Origin……Page 84

3.2.2.2 Establishment of Source Beds……Page 86

3.2.2.3 Nature of the Source Material……Page 88

3.2.2.4 Transformation of Organic Matter into Petroleum……Page 91

3.2.2.5 Accumulation in Reservoir Sediments……Page 92

3.2.2.6.1 Thermal Alteration……Page 97

3.2.2.6.2 Deasphalting……Page 99

3.2.3 Differences between the Abiogenic Theory and the Biogenic Theory……Page 100

3.2.4 Relationship of Petroleum Composition and Properties……Page 101

3.3 Occurrence……Page 103

3.3.1 Reserves……Page 104

3.3.2 Conventional Petroleum……Page 107

3.3.3 Natural Gas……Page 108

3.3.5 Bitumen (Extra Heavy Oil)……Page 110

References……Page 113

4.2 Properties……Page 117

4.4 Classification……Page 121

4.5 Isolation……Page 122

4.6.1 Ultimate (Elemental) Analysis……Page 123

4.6.3 Oxidation……Page 124

4.6.4 Thermal Methods……Page 125

4.7 Structural Models……Page 126

4.8 Kerogen Maturation……Page 128

References……Page 130

5.1 Introduction……Page 133

5.2 Exploration……Page 134

5.2.1 Gravity Methods……Page 135

5.2.2 Magnetic Methods……Page 136

5.2.3 Seismic Methods……Page 137

5.2.5 Electromagnetic Methods……Page 138

5.2.7 Borehole Logging……Page 139

5.3.1 Preparing to Drill……Page 140

5.3.2 Drilling Rig……Page 141

5.3.4 Drilling……Page 143

5.4 Well Completion……Page 144

5.5 Recovery……Page 145

5.5.1 Primary Recovery (Natural Methods)……Page 148

5.5.2 Secondary Recovery……Page 151

5.5.3 Enhanced Oil Recovery……Page 153

5.6 Products and Product Quality……Page 167

5.7 Transportation……Page 169

References……Page 174

6.1 Introduction……Page 177

6.2.1 Tar Sand Mining……Page 184

6.2.2 Hot-Water Process……Page 186

6.2.3 Other Processes……Page 189

6.3 Nonmining Methods……Page 191

6.3.1 Steam-Based Processes……Page 193

6.3.2 Combustion Processes……Page 194

6.3.3 Other Processes……Page 197

References……Page 207

Part II: Composition and Properties……Page 209

7.1 Introduction……Page 211

7.2 Ultimate (Elemental) Composition……Page 212

7.3 Chemical Components……Page 213

7.3.1 Hydrocarbon Constituents……Page 215

7.3.1.1 Paraffin Hydrocarbons……Page 216

7.3.1.2 Cycloparaffin Hydrocarbons (Naphthenes)……Page 218

7.3.1.3 Aromatic Hydrocarbons……Page 219

7.3.2 Nonhydrocarbon Constituents……Page 221

7.3.2.1 Sulfur Compounds……Page 222

7.3.2.3 Nitrogen Compounds……Page 224

7.3.2.4 Metallic Constituents……Page 226

7.3.2.5 Porphyrins……Page 227

7.4 Chemical Composition by Distillation……Page 229

7.4.1 Gases and Naphtha……Page 231

7.4.2 Middle Distillates……Page 232

7.4.3 Vacuum Residua (1050°F+)……Page 234

References……Page 235

8.1 Introduction……Page 239

8.2 Distillation……Page 241

8.2.1 Atmospheric Pressure……Page 244

8.2.2 Reduced Pressures……Page 245

8.2.3 Azeotropic and Extractive Distillation……Page 247

8.3 Solvent Treatment……Page 248

8.3.1.1 Influence of Solvent Type……Page 250

8.3.1.3 Influence of Temperature……Page 253

8.3.2 Fractionation……Page 254

8.4.1 Chemical Factors……Page 256

8.4.2.1 General Methods……Page 257

8.4.2.2 ASTM Methods……Page 261

8.5.1 Acid Treatment……Page 263

8.5.2.1 Urea Adduction……Page 265

8.5.2.3 Adduct Composition……Page 266

8.5.2.4 Adduct Structure……Page 267

8.5.2.5 Adduct Properties……Page 268

8.6 Use of the Data……Page 269

References……Page 271

9.1 Introduction……Page 273

9.2 Petroleum Assay……Page 274

9.3.1 Elemental (Ultimate) Analysis……Page 277

9.3.2 Density and Specific Gravity……Page 278

9.3.3 Viscosity……Page 280

9.3.4 Surface and Interfacial Tension……Page 283

9.3.5 Metals Content……Page 285

9.4.1 Volatility……Page 286

9.4.2 Liquefaction and Solidification……Page 289

9.4.3 Carbon Residue……Page 291

9.4.4 Aniline Point……Page 292

9.4.8 Thermal Conductivity……Page 293

9.4.11 Critical Properties……Page 294

9.5.3 Dielectric Strength……Page 295

9.5.5 Static Electrification……Page 296

9.6.1 Refractive Index……Page 297

9.7 Spectroscopic Methods……Page 298

9.7.2 Nuclear Magnetic Resonance……Page 299

9.8.1 Gas Chromatography……Page 300

9.8.2 Simulated Distillation……Page 303

9.8.3 Adsorption Chromatography……Page 304

9.8.4 Gel Permeation Chromatography……Page 305

9.8.5 Ion-Exchange Chromatography……Page 307

9.8.6 High-Performance Liquid Chromatography……Page 308

9.9 Molecular Weight……Page 309

9.10 Use of the Data……Page 310

References……Page 311

10.1 Introduction……Page 315

10.2 Methods for Structural Group Analysis……Page 317

10.2.1.1 Direct Method……Page 320

10.2.1.2 Waterman Ring Analysis……Page 322

10.2.1.4 n.d.M. Method……Page 323

10.2.1.6 Density-Temperature Coefficient Method……Page 324

10.2.1.7 Molecular Weight-Refractive Index Method……Page 325

10.2.1.8 Miscellaneous Methods……Page 326

10.2.2 Spectroscopic Methods……Page 327

10.2.2.1 Infrared Spectroscopy……Page 328

10.2.2.2 Nuclear Magnetic Resonance Spectroscopy……Page 331

10.2.2.3 Mass Spectrometry……Page 335

10.2.2.4 Electron Spin Resonance……Page 337

10.2.2.5 Ultraviolet Spectroscopy……Page 338

10.2.2.6 X-Ray Diffraction……Page 339

10.2.3.1 Nitrogen……Page 341

10.2.3.3 Sulfur……Page 342

10.3 Miscellaneous Methods……Page 343

References……Page 344

11.1 Introduction……Page 349

11.2 Separation……Page 350

11.3 Composition……Page 353

11.4 Molecular Weight……Page 358

11.5 Reactions……Page 362

11.6 Solubility Parameter……Page 367

11.7 Structural Aspects……Page 369

References……Page 375

12.1 Introduction……Page 379

12.2.1 Volatile Fractions……Page 380

12.2.2.2 Resins (Structure)……Page 381

12.2.3.2 Structure……Page 383

12.3 Chemical and physical structure of Petroleum……Page 384

12.4 Stability or Instability of the Crude Oil System……Page 389

12.5 Effects on Recovery and Refining……Page 398

12.5.1 Effects on Recovery Operations……Page 399

12.5.2 Effects on Refining Operations……Page 402

References……Page 404

13.1 Introduction……Page 407

13.2 Instability and Incompatibility in petroleum……Page 411

13.3.1 Elemental Analysis……Page 412

13.3.3 Volatility……Page 413

13.3.5 Asphaltene Content……Page 414

13.3.6 Pour Point……Page 415

13.3.8 Metals (Ash) Content……Page 416

13.4 Methods for Determining Instability and Incompatibility……Page 417

13.5 Effect of Asphaltene Constituents……Page 422

References……Page 425

Part III: Refining……Page 427

14.1 Introduction……Page 429

14.2 Dewatering and Desalting……Page 432

14.3 Early Processes……Page 433

14.4 Distillation……Page 434

14.4.1 Historical Development……Page 435

14.4.2.1 Atmospheric Distillation……Page 436

14.4.2.2 Vacuum Distillation……Page 437

14.5.1 Historical Development……Page 439

14.5.2.2 Visbreaking……Page 442

14.5.2.3 Coking……Page 443

14.6.1 Historical Development……Page 445

14.6.2 Modern Processes……Page 447

14.6.3 Catalysts……Page 448

14.7.2 Modern Processes……Page 449

14.8.1 Historical Development……Page 452

14.8.2.2 Catalytic Reforming……Page 453

14.8.2.3 Catalysts……Page 454

14.9.2 Modern Processes……Page 455

14.9.3 Catalysts……Page 456

14.10.2 Modern Processes……Page 457

14.11.2 Modern Processes……Page 458

14.12.1 Deasphalting……Page 459

14.12.2 Dewaxing……Page 460

14.13 Refining Heavy Feedstocks……Page 461

14.14 Petroleum Products……Page 465

14.15 Petrochemicals……Page 467

References……Page 468

15.1 Introduction……Page 471

15.2.1 Thermal Cracking……Page 473

15.2.2 Catalytic Cracking……Page 474

15.3 Hydrogenation……Page 477

15.3.2 Hydrotreating……Page 478

15.4 Isomerization……Page 479

15.6 Polymerization……Page 480

15.7.1 Thermal Chemistry……Page 481

15.7.2 Hydroconversion Chemistry……Page 490

15.7.3.1 Visbreaking……Page 491

15.7.3.2 Hydroprocessing……Page 494

References……Page 496

16.1 Introduction……Page 499

16.2 Pretreatment……Page 501

16.3 Atmospheric and Vacuum Distillation……Page 502

16.3.1 Atmospheric Distillation……Page 504

16.3.2 Vacuum Distillation……Page 507

16.4.1 Columns……Page 509

16.4.3 Trays……Page 511

16.5.1 Stripping……Page 512

16.5.3 Stabilization and Light End Removal……Page 513

16.5.4 Superfractionation……Page 514

16.5.5 Azeotropic Distillation……Page 515

16.5.6 Extractive Distillation……Page 517

16.5.7 Process Options for Heavy Feedstocks……Page 518

References……Page 519

17.1 Introduction……Page 521

17.2 Early Processes……Page 526

17.3 Commercial Processes……Page 527

17.3.1 Visbreaking……Page 528

17.3.2 Coking Processes……Page 533

17.3.2.1 Delayed Coking……Page 534

17.3.2.2 Fluid Coking……Page 537

17.3.2.3 Flexicoking……Page 539

17.3.3.2 Asphalt Coking Technology (ASCOT) Process……Page 541

17.3.3.3 Comprehensive Heavy Ends Reforming Refinery (Cherry-P) Process……Page 542

17.3.3.4 Decarbonizing……Page 543

17.3.3.6 Eureka Process……Page 544

17.3.3.7 Fluid Thermal Cracking (FTC) Process……Page 545

17.3.3.8 High Conversion Soaker Cracking (HSC) Process……Page 546

17.3.3.12 Shell Thermal Cracking……Page 549

17.3.3.13 Tervahl T Process……Page 551

References……Page 552

18.1 Introduction……Page 555

18.3 Commercial Processes……Page 559

18.3.2.1 Fluid-Bed Catalytic Cracking……Page 560

18.3.2.5 Universal Oil Products (UOP) Fluid-Bed Catalytic Cracking……Page 562

18.3.3.4 Suspensoid Catalytic Cracking……Page 563

18.3.4.1 Asphalt Residual Treating (ART) Process……Page 564

18.3.4.2 Residue Fluid Catalytic Cracking (HOC) Process……Page 565

18.3.4.3 Heavy Oil Treating (HOT) Process……Page 566

18.3.4.5 Reduced Crude Oil Conversion (RCC) Process……Page 567

18.3.4.6 Shell FCC Process……Page 568

18.3.4.7 S&W Fluid Catalytic Cracking Process……Page 570

18.4 Catalysts……Page 571

18.5 Process Parameters……Page 572

18.5.1 Reactor……Page 573

18.5.2 Coking……Page 574

18.5.3 Catalyst Variables……Page 576

18.5.4 Process Variables……Page 577

References……Page 578

19.2 Commercial Processes……Page 581

19.2.1 Deasphalting Process……Page 582

19.2.2 Process Options for Heavy Feedstocks……Page 588

19.2.2.1 Deep Solvent Deasphalting Process……Page 589

19.2.2.2 Demex Process……Page 592

19.2.2.3 MDS Process……Page 593

19.2.2.4 Residuum Oil Supercritical Extraction (ROSE) Process……Page 594

19.2.2.6 Lube Deasphalting……Page 595

19.3 Dewaxing Processes……Page 596

References……Page 601

20.1 Introduction……Page 603

20.2 Process Parameters and Reactors……Page 611

20.2.4 Catalyst Life……Page 612

20.2.5 Feedstock Effects……Page 613

20.2.6.1 Downflow Fixed-Bed Reactor……Page 615

20.2.6.2 Upflow Expanded-Bed Reactor……Page 616

20.3 Commercial Processes……Page 617

20.3.3 Gulf-HDS……Page 618

20.3.4 Hydrofining……Page 619

20.3.9 Process Options for Heavy Feedstocks……Page 621

20.3.9.1 Residuum Desulfurization and Vacuum Residuum Desulfurization Process……Page 622

20.3.9.2 Residfining Process……Page 623

20.4 Catalysts……Page 624

20.5 Biodesulfurization……Page 628

20.6 Gasoline and Diesel Fuel Polishing……Page 629

References……Page 631

21.1 Introduction……Page 633

21.2 Commercial Processes……Page 639

21.2.1.1 Single-Stage and Two-Stage Options……Page 640

21.2.2.2 CANMET Hydrocracking Process……Page 644

21.2.2.3 H-Oil Process……Page 646

21.2.2.5 Hyvahl F Process……Page 648

21.2.2.6 IFP Hydrocracking Process……Page 649

21.2.2.7 Isocracking Process……Page 650

21.2.2.8 LC-Fining Process……Page 651

21.2.2.10 Microcat-RC Process……Page 653

21.2.2.11 Mild Hydrocracking Process……Page 655

21.2.2.12 MRH Process……Page 656

21.2.2.14 Residfining Process……Page 657

21.2.2.16 Tervahl-H Process……Page 658

21.2.2.17 Unicracking Process……Page 659

21.2.2.18 Veba Combi Cracking Process……Page 661

21.3 Catalysts……Page 662

References……Page 669

22.1 Introduction……Page 671

22.2.1 Hydrotreating……Page 674

22.2.2 Hydrocracking……Page 675

22.3 Feedstocks……Page 676

22.4 Process Chemistry……Page 677

22.5 Commercial Processes……Page 679

22.5.1 Heavy Residue Gasification and Combined Cycle Power Generation……Page 680

22.5.4 Hypro Process……Page 681

22.5.5 Pyrolysis Processes……Page 682

22.5.7 Steam-Methane Reforming……Page 683

22.5.9 Synthesis Gas Generation……Page 685

22.5.10 Texaco Gasification (Partial Oxidation) Process……Page 686

22.6.1 Reforming Catalysts……Page 687

22.6.2 Shift Conversion Catalysts……Page 688

22.7 Hydrogen Purification……Page 689

22.7.2 Pressure-Swing Adsorption Units……Page 690

22.8 Hydrogen Management……Page 692

References……Page 693

23.1 Introduction……Page 695

23.2 Reforming……Page 696

23.2.1 Thermal Reforming……Page 698

23.2.2 Catalytic Reforming……Page 699

23.2.2.1.1 Hydroforming……Page 702

23.2.2.1.3 Platforming……Page 703

23.2.2.1.6 Selectoforming……Page 705

23.2.2.3 Fluid-Bed Processes……Page 706

23.3 Isomerization……Page 707

23.3.2 Butomerate Process……Page 709

23.3.7 Penex Process……Page 710

23.4 Alkylation……Page 711

23.4.1 Cascade Sulfuric Acid Alkylation……Page 712

23.4.2 Hydrogen Fluoride Alkylation……Page 713

23.5.1 Thermal Polymerization……Page 714

23.5.3 Bulk Acid Polymerization……Page 715

23.6.1 Reforming Processes……Page 716

23.6.4 Polymerization Processes……Page 717

References……Page 718

24.1 Introduction……Page 719

24.2.1 Caustic Processes……Page 722

24.2.1.5 Lye Treatment……Page 723

24.2.1.8 Sodasol Process……Page 724

24.2.2 Acid Processes……Page 725

24.2.2.2 Sulfuric Acid Treatment……Page 727

24.2.3.3 Bauxite Treatment……Page 728

24.2.3.8 Thermofor Continuous Percolation Process……Page 729

24.2.4.2 Copper Sweetening Process……Page 730

24.2.4.4 Hypochlorite Sweetening Process……Page 731

24.2.5 Solvent Processes……Page 732

24.2.5.1 Deasphalting……Page 733

24.2.5.2 Solvent Refining……Page 734

24.2.5.3 Dewaxing……Page 737

References……Page 740

25.1 Introduction……Page 741

25.1.1 Gas Streams from Crude Oil……Page 742

25.1.2 Gas Streams from Natural Gas……Page 745

25.2 Gas Cleaning……Page 746

25.3 Water Removal……Page 753

25.3.2 Solid Adsorbents……Page 754

25.3.3 Use of Membranes……Page 755

25.4.1 Extraction……Page 756

25.4.3 Fractionation of Natural Gas Liquids……Page 757

25.6 Acid Gas Removal……Page 758

25.8 Fractionation……Page 762

25.9 Claus Process……Page 763

References……Page 765

26.1 Introduction……Page 767

26.2.1 Composition……Page 772

26.2.3 Properties and Uses……Page 773

26.3.1 Composition……Page 776

26.3.2 Manufacture……Page 777

26.3.4 Octane Numbers……Page 780

26.3.5 Additives……Page 782

26.4.1 Composition……Page 784

26.4.2 Manufacture……Page 785

26.4.3 Properties and Uses……Page 787

26.5 Kerosene……Page 788

26.5.2 Manufacture……Page 789

26.6 Fuel Oil……Page 790

26.7 Lubricating Oil……Page 792

26.7.2 Manufacture……Page 793

26.7.2.3 Solvent Refining Processes……Page 794

26.7.2.6 Finishing Processes……Page 795

26.7.2.7 Older Processes……Page 796

26.7.3 Properties and Uses……Page 797

26.8.1 White Oil……Page 798

26.8.2 Insulating Oil……Page 799

26.9 Grease……Page 800

26.9.1 Lime Soap……Page 801

26.9.5 Cold Sett Grease……Page 802

26.10.2 Manufacture……Page 803

26.11.1 Composition……Page 805

26.11.2 Manufacture……Page 806

26.12 Coke……Page 808

26.13 Sulfonic Acids……Page 810

26.15 Product Blending……Page 811

References……Page 812

27.1 Introduction……Page 815

27.2.1 Halogenation……Page 823

27.2.2 Nitration……Page 824

27.2.3 Oxidation……Page 825

27.2.4 Alkylation……Page 826

27.3 Chemicals from Olefins……Page 827

27.3.1 Hydroxylation……Page 828

27.3.3 Polymerization……Page 830

27.4 Chemicals from Aromatics……Page 831

27.6 Chemicals from Natural Gas……Page 833

27.7 Inorganic Petrochemicals……Page 835

27.8 Synthesis Gas……Page 836

References……Page 837

Part IV: Environmental Issues……Page 839

28.1 Introduction……Page 841

28.2 Definitions……Page 843

28.3 Environmental Regulations……Page 845

28.3.3 Safe Drinking Water Act……Page 846

28.3.5 Toxic Substances Control Act……Page 847

28.3.8 Oil Pollution Act……Page 848

28.4 Process Analysis……Page 849

28.4.1 Gaseous Emissions……Page 852

28.4.2 Liquid Effluents……Page 856

28.4.3 Solid Effluents……Page 857

References……Page 858

29.1 Introduction……Page 861

29.2 Process Wastes……Page 864

29.2.1 Desalting……Page 865

29.2.2 Distillation……Page 866

29.2.3 Thermal Cracking and Visbreaking……Page 869

29.2.4 Coking Processes……Page 870

29.2.5 Fluid Catalytic Cracking……Page 872

29.2.6 Hydrocracking and Hydrotreating……Page 873

29.2.7 Catalytic Reforming……Page 876

29.2.8 Alkylation……Page 877

29.2.9 Isomerization……Page 879

29.2.10 Polymerization……Page 880

29.2.11 Deasphalting……Page 881

29.2.12 Dewaxing……Page 882

29.2.13 Gas Processing……Page 883

29.3 Types of Waste……Page 884

29.3.1 Gases and Lower Boiling Constituents……Page 886

29.3.2 Higher Boiling Constituents……Page 888

29.3.3 Wastewater……Page 889

29.4 Waste Toxicity……Page 891

29.5.3 Requirements……Page 892

29.6 Management of Refinery Waste……Page 893

References……Page 894

30.1 Introduction……Page 895

30.2 Petroleum and Petroleum Products……Page 896

30.4 Total Petroleum Hydrocarbons……Page 898

30.4.1 Gas Chromatographic Methods……Page 900

30.4.2 Infrared Spectroscopy Methods……Page 903

30.4.3 Gravimetric Methods……Page 904

30.4.4 Immunoassay Methods……Page 905

30.5 Petroleum Group Analysis……Page 906

30.5.2 Immunoassay……Page 907

30.5.3 Gas Chromatography……Page 908

30.5.4 High-Performance Liquid Chromatography……Page 909

30.5.5 Gas Chromatography-Mass Spectrometry……Page 910

30.7 Assessment of the Methods……Page 911

References……Page 914

SI Metric Conversion Factors (E = Exponent; I.E. E + 03 = 103)……Page 917

Glossary……Page 919

Reviews

There are no reviews yet.