C. B. Alcock0750651555, 9780750651554

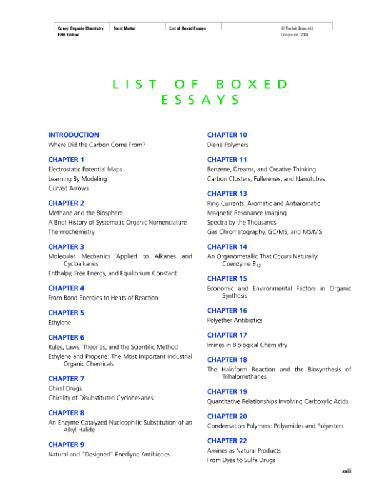

Table of contents :

Preface……Page 10

Part I Processes with Gaseous Reaction Control……Page 13

1.1 Vapour deposition for the preparation of thin films……Page 14

1.2 Materials science and the formation of thin films……Page 35

1.4 Appendix: Vapour pressure data for the elements……Page 49

2.1 Theories of reaction kinetics……Page 53

2.2 Thermal energies and the structures of molecules……Page 54

2.3 Combustion chain reactions……Page 64

2.5 Molecular dissociation and chain reactions in chemical vapour deposition……Page 73

2.6 Bibliography……Page 82

2.7 Radiation and electron decomposition of molecules……Page 83

2.8 Bibliography……Page 96

3.1 Vapour transport process……Page 97

3.2 The thermodynamics of the vapour phase transport of compounds……Page 104

3.3 Transport and thermal properties of gases……Page 119

3.4 Bibliography……Page 128

4.1 The zeroth order reaction……Page 129

4.2 Examples of industrially important catalysts……Page 140

4.3 Reactors for catalytic processes……Page 154

4.4 Bibliography……Page 156

Part II Rate Processes in the Solid State……Page 157

5.1 The transport of electrons and positive holes……Page 158

5.2 Thermal transport in condensed phases……Page 172

5.3 Heat capacities……Page 173

5.4 Bibliography……Page 178

6.1 Structure and diffusion-controlled processes in metallic systems……Page 179

6.2 Phase transformations in alloys……Page 193

6.4 Grain boundary and surface-driven properties in metallic systems……Page 204

6.5 Power metallurgy……Page 210

6.6 Bibliography……Page 230

7.1 Diffusion in elemental semiconductors……Page 232

7.2 Structures and diffusion in metal oxides……Page 233

7.3 Surfaces and surface energies in ionic crystals……Page 241

7.4 Sintering of metal oxides……Page 242

7.5 The production and application of ceramic oxide materials……Page 243

7.6 Bibliography……Page 259

8.1 The oxidation of metals and compounds……Page 260

8.2 Bibliography……Page 278

9.1 The reduction of haematite by hydrogen……Page 279

9.2 Erosion reactions of carbon by gases……Page 280

9.3 The combusion of coal……Page 282

9.4 The oxidation of FeS – parabolic to linear rate law transition……Page 283

9.5 Oxidation of complex sulphide ores – competitive oxidation of cations……Page 284

9.6 The kinetics of sulphation roasting……Page 285

9.7 Heat transfer in gas-solid reactions……Page 286

9.8 Industrial reactors for iron ore reduction to solid iron……Page 288

9.9 The industrial roasting of sulphides……Page 290

9.10 The corrosion of metals in multicompondent gases……Page 292

9.12 Appendix: Thermodynamic data for the Gibbs energy of formation of metal oxides……Page 294

Part III Process Involving Liquids……Page 298

10.1 The structures of mechanism of diffusion of liquid metals……Page 299

10.2 Thermophysical properties of liquid metals……Page 302

10.3 The production of metallic glasses……Page 306

10.4 Liquid metals in energy conversion……Page 308

10.5 Liquid phase sintering of refractory materials……Page 309

10.7 The production of crystalline semiconductors……Page 312

11 Physical and chemical properites of glassy and liquid silicates……Page 315

11.1 The production of silicate glasses and glass-containing materials……Page 318

11.2 Chalcogenide glasses……Page 323

11.3 Bibliography……Page 324

12 The structures and thermophysical properties of molten salts……Page 325

12.1 Hot corrosion of metals by molten salts……Page 327

12.2 Molten carbonate fuel cells……Page 329

12.3 Bibliography……Page 330

13 Extraction metallurgy……Page 331

13.1 The principles of metal extraction……Page 332

13.2 Extractive processes……Page 338

13.3 Steelmaking and copper production in pneumatic vessels……Page 345

13.4 The reduction of oxides and halides by reactive metals……Page 349

13.5 The electrolysis of molten salts……Page 355

13.6 Bibliography……Page 357

14 The refining of metals……Page 359

14.1 The refining of lead and zinc……Page 364

14.2 Vacuum refining of steel……Page 369

15 Factorial analysis of metal-production reactions……Page 373

15.1 Bibliography……Page 377

Index……Page 378

Reviews

There are no reviews yet.