Ed. by D. Vassalos et al.008-042263-2, 008-042266-7, 008-042821-5, 008-042826-6

Table of contents :

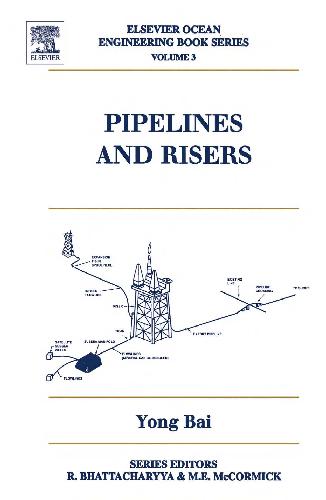

Front Cover……Page 1

Pipelines and Risers……Page 4

Copyright Page……Page 5

Table of Contents……Page 12

Series Preface……Page 6

Foreword……Page 8

Preface……Page 10

1.2 Design Stages and Process……Page 24

1.3 Design Through Analysis (DTA)……Page 30

1.4 Pipeline Design Analysis……Page 32

1.5 Pipeline Simulator……Page 42

1.6 References……Page 45

2.1 General……Page 46

2.2 Material Grade Selection……Page 47

2.3 Pressure Containment (hoop stress) Design……Page 49

2.4 Equivalent Stress Criterion……Page 54

2.5 Hydrostatic Collapse……Page 55

2.6 Wall Thickness and Length Design for Buckle Arrestors……Page 57

2.7 Buckle Arrestor Spacing Design……Page 58

2.8 References……Page 59

3.1 General……Page 62

3.2 Pipe Capacity under Single Load……Page 63

3.3 Pipe Capacity under Couple Load……Page 70

3.4 Pipes under Pressure Axial Force and Bending……Page 72

3.5 Finite Element Model……Page 78

3.6 References……Page 84

4.1 Introduction……Page 86

4.2 Out of Roundness Serviceability Limit……Page 87

4.3 Bursting……Page 88

4.4 Local Buckling/Collapse……Page 90

4.5 Fracture……Page 93

4.6 Fatigue……Page 96

4.9 Accumulated Plastic Strain……Page 98

4.11 References……Page 99

5.2 Pipe Penetration in Soil……Page 102

5.3 Modeling Friction and Breakout Forces……Page 105

5.4 References……Page 106

6.3 Mathematical Formulations used in the Wave Simulators……Page 108

6.4 Steady Currents……Page 113

6.5 Hydrodynamic Forces……Page 114

6.6 References……Page 118

7.1 Introduction……Page 120

7.2 Description of the Finite Element Model……Page 121

7.3 Steps in an Analysis and Choice of Analysis Procedure……Page 124

7.4 Element Types used in the Model……Page 125

7.5 Non-linearity and Seabed Model……Page 127

7.7 References……Page 129

8.1 General……Page 132

8.3 Acceptance Criteria……Page 133

8.4 Special Purpose Program for Stability Analysis……Page 134

8.5 Use of FE Analysis for Intervention Design……Page 137

8.6 References……Page 139

9.1 General……Page 140

9.2 Free-span VIV Analysis Procedure……Page 142

9.3 Fatigue Design Criteria……Page 147

9.4 Response Amplitude……Page 148

9.5 Modal Analysis……Page 152

9.6 Example Cases……Page 154

9.7 References……Page 158

10.1 Introduction……Page 160

10.2 Fatigue Analysis……Page 161

10.3 Force Model……Page 167

10.4 Comparisons of Frequency Domain and Time Domain Approaches……Page 175

10.5 Conclusions and Recommendations……Page 176

10.6 References……Page 177

11.2 Trawl Gears……Page 178

11.3 Acceptance Criteria……Page 179

11.4 Impact Response Analysis……Page 180

11.5 Pullover Loads……Page 189

11.6 Finite Element Model for Pullover Response Analyses……Page 191

11.7 Case Study……Page 193

11.8 References……Page 198

12.1 Introduction……Page 200

12.2 Pipeline Installation Vessels……Page 201

12.3 Software OFFPIPE and Code Requirements……Page 208

12.4 Physical Background for Installation……Page 209

12.5 Finite Element Analysis Procedure for Installation of In-line Valves……Page 227

12.6 Two Medium Pipeline Design Concept……Page 232

12.7 References……Page 239

13.1 General……Page 242

13.2 Reliability-based Design……Page 243

13.3 Uncertainty Measures……Page 245

13.4 Calibration of Safety Factors……Page 246

13.5 Buckling/Collapse of Corroded Pipes……Page 247

13.7 References……Page 250

14.1 Introduction……Page 252

14.2 Review of Existing Criteria……Page 253

14.3 Development of New Criteria……Page 260

14.5 Reliability-based Design……Page 263

14.6 Example Applications……Page 269

14.8 References……Page 277

15.1 Introduction……Page 280

15.2 Fracture of Pipes with Longitudinal Cracks……Page 281

15.3 Fracture of Pipes with Circumferential Cracks……Page 285

15.4 Reliability-based Assessment and Calibration of Safety Factors……Page 286

15.5 Design Examples……Page 290

15.7 References……Page 297

16.1 Introduction……Page 300

16.2 Acceptance Criteria……Page 302

16.4 Cause Analysis……Page 306

16.5 Probability of Initiating Events……Page 307

16.6 Causes of Risks……Page 310

16.7 Consequence Analysis……Page 311

16.8 Example 1: Risk analysis for a Subsea Gas Pipeline……Page 315

16.9 Example 2: Dropped Object Risk Analysis……Page 321

16.10 References……Page 326

17.2 Pipeline Routing……Page 328

17.3 Pipeline Tie-ins……Page 330

17.4 Flowline Trenching/Burying……Page 338

17.5 Flowline Rockdumping……Page 342

17.7 References……Page 346

18.1 Operations……Page 348

18.2 Inspection by Intelligent Pigging……Page 353

18.3 Maintenance……Page 363

18.4 Pipeline Repair Methods……Page 365

18.5 Deepwater Pipeline Repair……Page 373

18.6 References……Page 375

19.1 Review of Usage of High Strength Steel Linepipes……Page 376

19.2 Potential Benefits and Disadvantages of High Strength Steel……Page 390

19.3 Welding of High Strength Linepipe……Page 394

19.4 Cathodic Protection……Page 397

19.5 Fatigue and Fracture of High Strength Steel……Page 398

19.6 Material Property Requirements……Page 399

19.7 References……Page 402

20.2 Descriptions of Riser System……Page 404

20.3 Metallic Catenary Riser for Deepwater Environments……Page 409

20.4 Stresses and Service Life of Flexible Pipes……Page 413

20.6 Riser Projects in Norway……Page 414

20.7 References……Page 415

21.1 Design Guidelines for Marine Riser Design……Page 416

21.2 Design Criteria for Deepwater Metallic Risers……Page 418

21.3 Limit State Design Criteria……Page 420

21.4 Design Conditions and Loads……Page 422

21.5 Improving Design Codes and Guidelines……Page 427

21.6 Comparison of lSO and API Codes with Hauch and Bai (1999)……Page 429

21.7 References……Page 434

22.2 Fatigue Causes……Page 436

22.3 Riser VIV Analysis Program……Page 441

22.4 Flexible Riser Analysis Program……Page 442

22.5 Vortex-induced Vibration Prediction……Page 444

22.6 Fatigue Life……Page 445

22.8 Fatigue of Deepwater Metallic Risers……Page 446

22.9 References……Page 453

23.2 Design Criteria……Page 456

23.3 Load Cases……Page 459

23.4 Finite Element Models……Page 460

23.5 References……Page 462

24.2 Pipe-in-Pipe System……Page 464

24.3 Bundle System……Page 474

24.4 References……Page 488

25.1 Introduction……Page 490

25.2 Initial Cost……Page 492

25.3 Financial Risk……Page 495

25.4 Time value of Money……Page 498

25.5 Fabrication Tolerance Example Using the Life-Cycle Cost Model……Page 499

25.6 On-Bottom Stability Example……Page 508

25.7 References……Page 510

26.2 Åsgard Flowlines Project……Page 512

26.3 Åsgard Transport Project……Page 515

26.4 References……Page 518

Subject Index……Page 520

Reviews

There are no reviews yet.