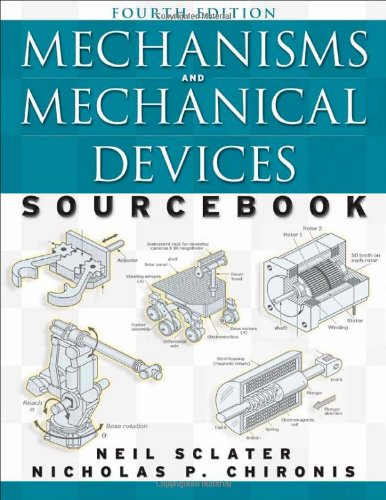

Neil Sclater, Nicholas Chironis0-07-146761-0, 978-0-07-146761-2

The fourth edition of this unique engineering reference book covers the past, present, and future of mechanisms and mechanical devices. Among the thousands of proven mechanisms illustrated and described are many suitable for recycling into new mechanical, electromechanical, or mechatronic products and systems. Overviews of robotics, rapid prototyping, MEMS, and nanotechnology will get you up-to-speed on these cutting-edge technologies. Easy-to-read tutorial chapters on the basics of mechanisms and motion control will introduce those subjects to you or refresh your knowledge of them.

Comprehensive index to speed your search for topics of interest Glossaries of terms for gears, cams, mechanisms, and robotics New industrial robot specifications and applications Mobile robots for exploration, scientific research, and defense

INSIDE Mechanisms and Mechanical Devices Sourcebook, 4th Edition

Basics of Mechanisms • Motion Control Systems • Industrial Robots • Mobile Robots • Drives and Mechanisms That Include Linkages, Gears, Cams, Genevas, and Ratchets • Clutches and Brakes • Devices That Latch, Fasten, and Clamp • Chains, Belts, Springs, and Screws • Shaft Couplings and Connections • Machines That Perform Specific Motions or Package, Convey, Handle, or Assure Safety • Systems for Torque, Speed, Tension, and Limit Control • Pneumatic, Hydraulic, Electric, and Electronic Instruments and Controls • Computer-Aided Design Concepts • Rapid Prototyping • New Directions in Mechanical Engineering

Table of contents :

Front Matter……Page 1

Table of Contents……Page 0

Preface……Page 3

Table of Contents……Page 5

1. Basics of Mechanisms……Page 11

1.2.2 Mechanical Advantage……Page 12

1.4 Pulley Systems……Page 13

1.6.1 Levers……Page 14

1.7.1 Simple Planar Linkages……Page 15

1.7.2 Specialized Linkages……Page 16

1.7.3 Straight-Line Generators……Page 17

1.7.4 Rotary/Linear Linkages……Page 18

1.8 Specialized Mechanisms……Page 19

1.9 Gears and Gearing……Page 20

1.9.3 Gear Classification……Page 21

1.9.4 Practical Gear Configurations……Page 22

1.9.7 Gear Dynamics Terminology……Page 23

1.12 Cam Mechanisms……Page 24

1.12.1 Classification of Cam Mechanisms……Page 25

1.13.2 Externally Controlled Positive Clutches……Page 27

1.14 Glossary of Common Mechanical Terms……Page 28

2. Motion Control Systems……Page 31

2.1.4 Closed-Loop System……Page 32

2.1.5 Trapezoidal Velocity Profile……Page 33

2.1.11 Mechanical Components……Page 34

2.1.13 Motor Selection……Page 36

2.1.15 Feedback Sensors……Page 37

2.2 Glossary of Motion Control Terms……Page 38

2.3 Mechanical Components Form Specialized Motion-Control Systems……Page 39

2.4.2 Brush-Type PM DC Servomotors……Page 40

2.4.4 Cup-or Shell-Type PM DC Motors……Page 41

2.4.5 Brushless PM DC Motors……Page 42

2.4.10 Linear Servomotors……Page 43

2.4.11 Commutation……Page 44

2.4.15 Stepper Motors……Page 45

2.4.19 Stepper Motor Applications……Page 46

2.4.21 Stepper-Motor Based Linear Actuators……Page 47

2.5.2 Incremental Encoders……Page 48

2.5.4 Linear Encoders……Page 49

2.5.6 Resolvers……Page 50

2.5.7 Tachometers……Page 51

2.5.9 Linear Velocity Transducers (LVTs)……Page 52

2.5.12 Laser Interferometers……Page 53

2.5.13 Precision Multiturn Potentiometers……Page 54

2.6.2 Technical Considerations……Page 55

2.6.7 Rotary Solenoids……Page 56

2.6.8 Rotary Actuators……Page 57

3. Industrial Robots……Page 59

3.1.1 Economic Importance of Robots……Page 60

3.2 Industrial Robots……Page 61

3.2.1 Industrial Robot Advantages……Page 62

3.2.3 Industrial Robot Geometry……Page 63

3.2.7 M-900iA Series Robots……Page 66

3.3 Mechanism for Planar Manipulation with Simplified Kinematics……Page 70

3.4 Tool-Changing Mechanism for Robot……Page 71

3.5 Piezoelectric Motor in Robot Finger Joint……Page 72

3.6 Self-Reconfigurable, Two-Arm Manipulator with Bracing……Page 73

3.6.1 Improved Roller and Gear Drives for Robots and Vehicles……Page 74

3.7 Glossary of Robotic Terms……Page 75

4. Mobile Scientific, Military, and Research Robots……Page 77

4.1 Introduction to Mobile Robots……Page 78

4.2 Scientific Mobile Robots……Page 79

4.3 Military Mobile Robots……Page 80

4.4.2 M-Tran II Robots……Page 82

4.4.3 Polybot Robots……Page 83

4.4.5 Swarming Robots……Page 84

4.4.7 A Single-Wheel Stabilized Robot……Page 85

4.5 Second-Generation Six-Limbed Experimental Robot……Page 86

4.6 All-Terrain Vehicle with Self-Righting and Pose Control……Page 87

4.6.1 Resources……Page 88

5. Linkages: Drives and Mechanisms……Page 89

5.1 Four-Bar Linkages and Typical Industrial Applications……Page 90

5.2 Seven Linkages for Transport Mechanisms……Page 92

5.3 Five Linkages for Straight-Line Motion……Page 95

5.4 Six Expanding and Contracting Linkages……Page 97

5.5 Four Linkages for Different Motions……Page 98

5.6 Nine Linkages for Accelerating and Decelerating Linear Motions……Page 99

5.7 Twelve Linkages for Multiplying Short Motions……Page 101

5.9 Seven Stroke Multiplier Linkages……Page 103

5.10 Nine Force and Stroke Multiplier Linkages……Page 105

5.11 Eighteen Variations of Differential Linkage……Page 107

5.12.1 The Practical Nine……Page 109

5.12.2 The Mavericks……Page 110

5.13.1 Spherical Crank Drive……Page 111

5.13.3 Skewed Hooke’s Joint Drive……Page 112

5.13.5 The 3-D Crank Slide Drive……Page 113

5.13.6 The Space Crank Drive……Page 114

5.13.7 The Elliptical Slide Drive……Page 115

5.14 Thirteen Different Toggle Linkage Applications……Page 116

5.15 Hinged Links and Torsion Bushings Soft-Start Drives……Page 118

5.16 Eight Linkages for Band Clutches and Brakes……Page 119

5.17 Design of Crank-and-Rocker Links for Optimum Force Transmission……Page 121

5.18 Design of Four-Bar Linkages for Angular Motion……Page 124

5.19 Multibar Linkages for Curvilinear Motions……Page 125

5.19.1 Synthesis of an Eight-Bar Linkage……Page 127

5.20.3 Special Case……Page 128

5.21 Slider-Crank Mechanism……Page 129

6. Gears: Devices, Drives, and Mechanisms……Page 130

6.1 Gears and Eccentric Disk Provide Quick Indexing……Page 131

6.2 Odd-Shaped Planetary Gears Smooth Stop and Go……Page 132

6.3 Cycloid Gear Mechanism Controls Pump Stroke……Page 135

6.5 Twin-Motor Planetary Gears Offer Safety and Dual-Speed……Page 136

6.6 Eleven Cycloid Gear Mechanisms……Page 137

6.7 Five Cardan-Gear Mechanisms……Page 140

6.8 Controlled Differential Gear Drives……Page 142

6.9 Flexible Face-Gears are Efficient High-Ratio Speed Reducers……Page 143

6.10 Rotary Sequencer Gears Turn Coaxially……Page 144

6.11 Planetary Gear Systems……Page 145

6.12.2 Noncircular Gears……Page 152

6.12.3 Design Equations……Page 153

6.12.4 Checking for Closed Curves……Page 154

6.13 Sheet-Metal Gears, Sprockets, Worms, and Ratchets for Light Loads……Page 156

6.14 Thirteen Ways Gears and Clutches Can Change Speed Ratios……Page 158

6.15 Gear and Clutch Shifting Mechanisms……Page 160

6.15.1 Spiderless Differential……Page 161

6.16.1 Jobs for the New Drive……Page 162

6.17 Elastomeric Gear Bearings Equalize Torque Loads……Page 163

6.18 Redundant Gearing in Helicopter Transmits Torque……Page 164

6.19 Worm Gear Friction Reduced by Oil Pressure……Page 165

6.20 Bevel and Hypoid Gear Design Prevents Undercutting……Page 166

6.21 Geared Electromechanical Rotary Joint……Page 167

6.22 Geared Speed Reducers Offer One-Way Output……Page 168

6.23 Design of Geared Five-Bar Mechanisms……Page 169

6.24 Equations for Designing Geared Cycloid Mechanisms……Page 173

6.25 Design Curves and Equations for Gear-Slider Mechanisms……Page 176

6.25.5 Design Charts……Page 177

6.25.8 Output Motion……Page 178

6.25.10 Future Modifications……Page 179

7. Cam, Geneva, and Ratchet Drives and Mechanisms……Page 180

7.1.3 Design Procedure……Page 181

7.2 Five Cam-Stroke-Amplifying Mechanisms……Page 182

7.3.2 Constant-Velocity Cams……Page 183

7.3.4 Cycloidal Motion……Page 184

7.3.6 Generating Modified Cycloidals……Page 185

7.3.8 Compensating for Dwells……Page 186

7.3.9 Double-Genevas with Differential……Page 187

7.3.11 Double Eccentric Drive……Page 188

7.4 Fifteen Different Cam Mechanisms……Page 189

7.5 Ten Special-Function Cams……Page 191

7.6 Twenty Geneva Drives……Page 193

7.7 Six Modified Geneva Drives……Page 197

7.8 Kinematics of External Geneva Wheels……Page 199

7.9 Kinematics of Internal Geneva Wheels……Page 202

7.10 Star Wheels Challenge Geneva Drives for Indexing……Page 206

7.12 Modified Ratchet Drive……Page 209

7.13 Eight Toothless Ratchets……Page 210

7.14 Analysis of Ratchet Wheels……Page 211

8. Clutches and Brakes……Page 212

8.1 Twelve Clutches with External or Internal Control……Page 213

8.2.3 Brake and Clutch Combinations……Page 215

8.2.4 Design Example……Page 216

8.3 Controlled-Slip Expands Spring Clutch Applications……Page 217

8.4 Spring Bands Improve Overrunning Clutch……Page 218

8.5.1 Eight-Joint Coupler……Page 219

8.6 Walking Pressure Plate Delivers Constant Torque……Page 220

8.7 Seven Overrunning Clutches……Page 221

8.9 Roller Clutch Provides Two Output Speeds……Page 222

8.10 Seven Overriding Clutches……Page 223

8.11 Ten Applications for Overrunning Clutches……Page 225

8.12 Eight Sprag Clutch Applications……Page 227

8.13 Six Small Clutches Perform Precise Tasks……Page 229

8.14 Twelve Different Station Clutches……Page 231

8.15.3 Purely Magnetic Clutches……Page 234

8.15.7 Other Magnetic Clutches……Page 235

8.16 Roller Locking Mechanism Contains Two Overrunning Clutches……Page 236

9. Latching, Fastening, and Clamping Devices and Mechanisms……Page 237

9.1 Sixteen Latch, Toggle, and Trigger Devices……Page 238

9.2 Fourteen Snap-Action Devices……Page 240

9.3 Remote Controlled Latch……Page 244

9.5 Grapple Frees Loads Automatically……Page 245

9.7 Automatic Brake Locks Hoist When Driving Torque Ceases……Page 246

9.9 Perpendicular-Force Latch……Page 247

9.10 Two Quick-Release Mechanisms……Page 248

9.12 Cammed Jaws in Hydraulic Cylinder Grip Sheet Metal……Page 249

9.13 Quick-Acting Clamps for Machines and Fixtures……Page 250

9.14 Nine Friction Clamping Devices……Page 252

9.15 Detents for Stopping Mechanical Movements……Page 254

9.16 Twelve Clamping Methods for Aligning Adjustable Parts……Page 256

9.17 Spring-Loaded Chucks and Holding Fixtures……Page 258

10. Chain and Belt Devices and Mechanisms……Page 259

10.1.1 Belt Drives……Page 260

10.1.2 Sheave Drives……Page 261

10.1.3 Chain Drives……Page 262

10.2 Belts and Chains are Available in Many Different Forms……Page 263

10.2.1 Steel Belts for Reliability……Page 264

10.2.3 Parallel-Cable Drives……Page 265

10.2.4 A Traditional Note……Page 266

10.4 Motor Mount Pivots to Control Belt Tension……Page 267

10.5 Ten Roller Chains and Their Adaptations……Page 268

10.6 Twelve Applications for Roller Chain……Page 270

10.7 Six Mechanisms for Reducing Pulsations in Chain Drives……Page 274

11. Spring and Screw Devices and Mechanisms……Page 276

11.1 Flat Springs in Mechanisms……Page 277

11.2 Twelve Ways to Use Metal Springs……Page 279

11.3 Seven Overriding Spring Mechanisms for Low-Torque Drives……Page 281

11.4 Six Spring Motors and Associated Mechanisms……Page 283

11.5.1 Bellows Type……Page 285

11.5.3 Rolling-Diaphragm Type……Page 286

11.6 Novel Applications for Different Springs……Page 287

11.7 Applications for Belleville Springs……Page 288

11.8 Vibration Control with Spring Linkage……Page 289

11.9 Twenty Screw Devices……Page 290

11.10 Ten Applications for Screw Mechanisms……Page 293

11.11 Seven Special Screw Arrangements……Page 294

11.12 Fourteen Spring and Screw Adjusting Devices……Page 295

12. Shaft Couplings and Connections……Page 296

12.1 Four Couplings for Parallel Shafts……Page 297

12.2 Links and Disks Couple Offset Shafts……Page 298

12.3 Disk-and-Link Couplings Simplify Torque Transmission……Page 299

12.4 Interlocking Space-Frames Flex as They Transmit Shaft Torque……Page 300

12.4.2 List of Symbols……Page 301

12.5 Coupling with Off-Center Pins Connects Misaligned Shafts……Page 302

12.6 Universal Joint Transmits Torque 45° at Constant Speed……Page 303

12.7.2 Constant-Velocity Couplings……Page 304

12.8 Nineteen Methods for Coupling Rotating Shafts……Page 306

12.9 Five Different Pin-and-Link Couplings……Page 310

12.10 Ten Different Splined Connections……Page 311

12.11 Fourteen Ways to Fasten Hubs to Shafts……Page 313

13. Motion-Specific Devices, Mechanisms, and Machines……Page 315

13.1 Timing Belts, Four-Bar Linkage Team Up for Smooth Indexing……Page 316

13.2 Ten Indexing and Intermittent Mechanisms……Page 318

13.3 Twenty-Seven Rotary-to-Reciprocating Motion and Dwell Mechanisms……Page 320

13.3.2 Fast Cam-Follower Motion……Page 324

13.4 Five Friction Mechanisms for Intermittent Rotary Motion……Page 326

13.5 Nine Different Ball Slides for Linear Motion……Page 328

13.6 Ball-Bearing Screws Convert Rotary to Linear Motion……Page 330

13.7 Nineteen Arrangements for Changing Linear Motion……Page 331

13.8 Five Adjustable-Output Mechanisms……Page 335

13.9 Four Different Reversing Mechanisms……Page 337

13.10 Ten Mechanical Computing Mechanisms……Page 338

13.11 Seven Different Mechanical Power Amplifiers……Page 342

13.12 Forty-Three Variable-Speed Drives and Transmissions……Page 345

13.14 Ten Variable-Speed Friction Drives……Page 357

13.15 Four Drives Convert Oscillating Motion to One-Way Rotation……Page 359

13.15.4 Reciprocating-Ball Drive……Page 360

13.16 Operating Principles of Liquid, Semisolid, and Vacuum Pumps……Page 361

13.17 Twelve Different Rotary-Pump Actions……Page 365

14. Packaging, Conveying, Handling, and Safety Mechanisms and Machines……Page 367

14.1 Fifteen Devices That Sort, Feed, or Weigh……Page 368

14.2 Seven Cutting Mechanisms……Page 372

14.4 One Vibrating Mechanism……Page 374

14.5 Seven Basic Parts Selectors……Page 375

14.6 Eleven Parts-Handling Mechanisms……Page 376

14.7 Seven Automatic-Feed Mechanisms……Page 378

14.8 Fifteen Conveyor Systems for Production Machines……Page 381

14.9 Seven Traversing Mechanisms for Winding Machines……Page 385

14.11 Machine Applies Labels from Stacks or Rollers……Page 387

14.12 Twenty High-Speed Machines for Applying Adhesives……Page 388

14.13 Twenty-Four Automatic Mechanisms for Stopping Unsafe Machines……Page 394

14.14 Six Automatic Electrical Circuits for Stopping Textile Machines……Page 400

14.15 Six Automatic Mechanisms for Assuring Safe Machine Operation……Page 402

15. Torque, Speed, Tension, and Limit Control Systems……Page 404

15.1 Applications of the Differential Winch to Control Systems……Page 405

15.2 Six Ways to Prevent Reverse Rotation……Page 407

15.4 Control System for Paper Cutting……Page 408

15.6 Lever System Monitors Cable Tension……Page 409

15.7 Eight Torque-Limiters Protect Light-Duty Drives……Page 410

15.8 Thirteen Limiters Prevent Overloading……Page 411

15.9 Seven Ways to Limit Shaft Rotation……Page 414

15.10 Mechanical Systems for Controlling Tension and Speed……Page 416

15.11 Nine Drives for Controlling Tension……Page 420

15.12 Limit Switches in Machinery……Page 423

15.13 Nine Automatic Speed Governors……Page 427

15.14 Eight Speed Control Devices for Mechanisms……Page 429

16. Instruments and Controls: Pneumatic, Hydraulic, Electric, and Electronic……Page 430

16.1 Twenty-Four Mechanisms Actuated by Pneumatic or Hydraulic Cylinders……Page 431

16.3 Fifteen Tasks for Pneumatic Power……Page 433

16.4 Ten Applications for Metal Diaphragms and Capsules……Page 435

16.5 Nine Differential Transformer Sensors……Page 437

16.6 High-Speed Electronic Counters……Page 439

16.7 Applications for Permanent Magnets……Page 440

16.8 Nine Electrically Driven Hammers……Page 443

16.9 Sixteen Thermostatic Instruments and Controls……Page 445

16.10 Eight Temperature-Regulating Controls……Page 449

16.11 Seven Photoelectric Controls……Page 451

16.12 Liquid Level Indicators and Controllers……Page 453

16.13 Applications for Explosive-Cartridge Devices……Page 455

16.13.1 Quick Disconnector……Page 456

16.14 Centrifugal, Pneumatic, Hydraulic, and Electric Governors……Page 457

17. Computer-Aided Design Concepts……Page 459

17.1.1 Two-Dimensional Drafting……Page 460

17.1.2 Three-Dimensional Solid Modeling……Page 461

17.1.3 Three-Dimensional Feature-Based Solid Modeling……Page 462

17.1.5 Glossary of Commonly Used CAD Terms……Page 464

18. Rapid Prototyping……Page 465

18.2 Rapid Prototype Processes……Page 466

18.4 Commercial Rapid Prototyping Choices……Page 467

18.4.1 Stereolithography (SL)……Page 468

18.4.2 Selective Laser Sintering (SLS)……Page 469

18.4.3 Laminated Object Manufacturing (LOM)……Page 470

18.4.5 Three Dimensional Printing (3DP)……Page 471

18.4.6 Directed Light Fabrication (DLF)……Page 472

18.4.8 Solid Ground Curing (SGC)……Page 473

18.4.11 Shape Deposition Manufacturing (SDM)……Page 474

18.4.14 Resource……Page 475

19. New Directions in Mechanical Engineering……Page 476

19.1.1 Microtechnology Today……Page 477

19.1.2 Microtechnology Tomorrow……Page 478

19.2.1 The Microactuators……Page 479

19.2.2 Materials……Page 480

19.2.5 Piezoelectric Films……Page 481

19.2.7 Surface Micromachining……Page 482

19.4 Gallery of Mems Electron-Microscope Images……Page 483

19.5.3 Early Research and Development……Page 487

19.5.6 Micromechanical Actuators……Page 488

19.6 Alternative Materials for Building MEMS……Page 489

19.7 LIGA: An Alternative Method for Making Microminiature Parts……Page 490

19.8 Miniature Multispeed Transmissions for Small Motors……Page 491

19.9 The Role of Nanotechnology in Mechanical Engineering……Page 492

19.10 What are Carbon Nanotubes?……Page 494

19.11 Nanoactuators Based on Electrostatic Forces on Dielectrics……Page 495

19.11.1 Resources……Page 496

A……Page 497

B……Page 498

C……Page 499

D……Page 508

E……Page 514

G……Page 515

I……Page 520

J……Page 521

L……Page 522

M……Page 526

P……Page 539

R……Page 541

S……Page 545

T……Page 549

W……Page 551

Reviews

There are no reviews yet.